HYNAUT Equipment intelligent management project

After HYNAUT Group's equipment was connected to the cloud, the production efficiency and timely delivery rate of orders have significantly improved, and the maintenance and management costs of enterprise equipment have decreased.

Customer Profile

Case background

Device data opacity

All devices are not connected to the internet, and device information relies on manual estimation. At the group level, it is impossible to perceive the actual situation of equipment and production in each factory;

Multiple customized orders

Hundreds of products with special requirements and standards, time-consuming and labor-intensive production scheduling, and frequent errors, causing losses to the enterprise;

High equipment failure rate

There are many devices that frequently shut down, waste production capacity, slow improvement of production energy efficiency, and many cases of delayed order delivery;

No maintenance systematic

Regular manual maintenance is only reported after equipment malfunctions;

Chaotic management of spare parts

Full manual management mode with no standard management regulations, frequent errors in inbound and outbound operations, and no knowledge of the actual and quantity of equipment replacement parts, resulting in significant pressure on procurement and warehousing

Implementation details

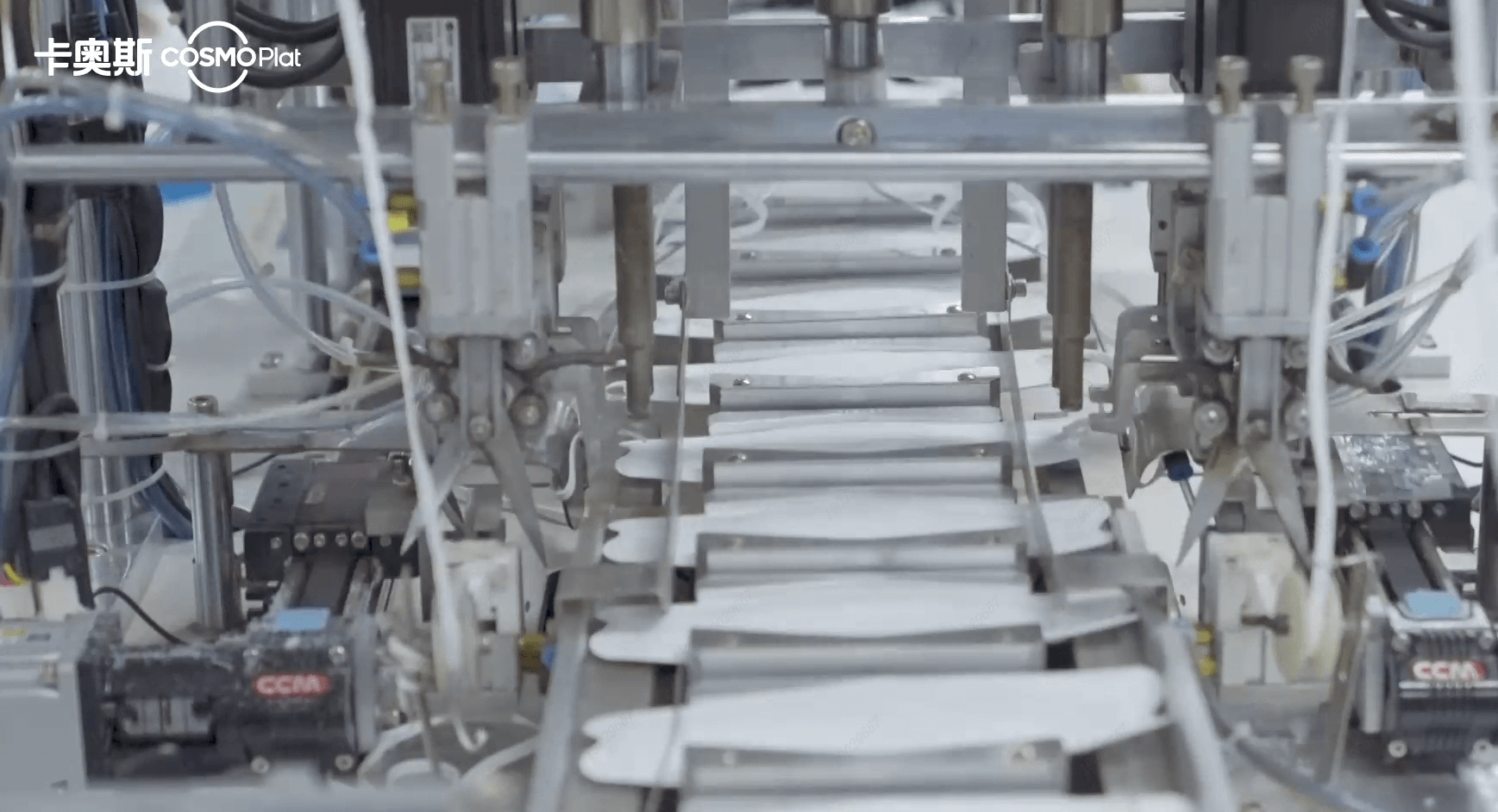

Real time data acquisition, transparent and visible

The devices are connected to the cloud, and the edge gateway collects real-time device data. The device status and production data are clear and transparent, achieving centralized networking and comprehensive management of group level devices

Data analysis and intelligent decision-making

The big data platform aggregates massive equipment data, intelligently analyzes key indicators of equipment comprehensive production efficiency, procurement cost, and energy consumption, establishes equipment archives and fault knowledge bases, optimizes maintenance plans, and provides precise data support for strategic business decisions.

Order scheduling and optimization plan

Relying on equipment data to assist production scheduling, helping enterprises optimize production processes and track them in a timely manner, effectively managing order scheduling and execution in real-time, reducing the probability of equipment failures, and improving the efficiency of comprehensive equipment management

Cloud based SaaS, solid and reliable

Relying on the COSMOPlat Bass engine, providing an active three-layer defense system to provide security protection for enterprise data

Achievement Introductions

Customer testimony